I've been working on my 03 R1 track bike for the last week yanking the engine out due to a snapped crank. After a few hours of electrical connectors and throttle bodies and incredibly cramped working spaces in the R1 frame - getting into the GT was like stepping back to cave man days, so simple to work on, quite rejuvenating.

Build plan for the bike is:

92 GSXR750 front end swap

new 36 spoke GSXR hub

17x2.75" or 3 alum rim on the front

look into widening the stock rear swingarm if possible

if the widening works out then some add some top swingarm bracing

17x4.25" alum rim on the stock rear hub

chrome spokes from Buchannan, really wanting to stay with the spoke look but on a wider track with access to all the 17" rubber

Jemco's painted black

Uni pods

recover the seat

Koni's or equiv in the rear

replace all the phillips screws with hex head bolts, in fact hex head will be used where ever possible

electronic ignition

So first thing is to get it running before really tearing into it. With all the rust in the tank the first thing is to drain it and get it prepped for electrolysis cleaning. Petcock has a known shutoff problem so prev owner installed an inline shut off, and vacuum input port of the petcock is blocked off. Assuming something wrong with the diaphragm. Grab the 5 gal gas jug, unscrew the 9mm line from the carb inlet, drop the line into the jug and turn the petcock/inline on to drain the tank. Thing pisses fuel out slower than an old man with a prostate issue. Ok... Grab big funnel and put it in the top of the jug, pull the tank off and flip it upside down to get it drained out of the filler hole. Gas is a bit discolored, some dust in the bottom of the jug. Put the tank on the bench to get the petcock off.

Just a bit of debris. This is after I knocked a bunch of rust off before I remembered to grab the camera to help document the project.

The spacer:

Something has knocked a notch out of the spacer at the 6 o'clock position, you can see that the o-ring has some distortion. But no tear and looks fine to reuse.

Crud was piled up high on this:

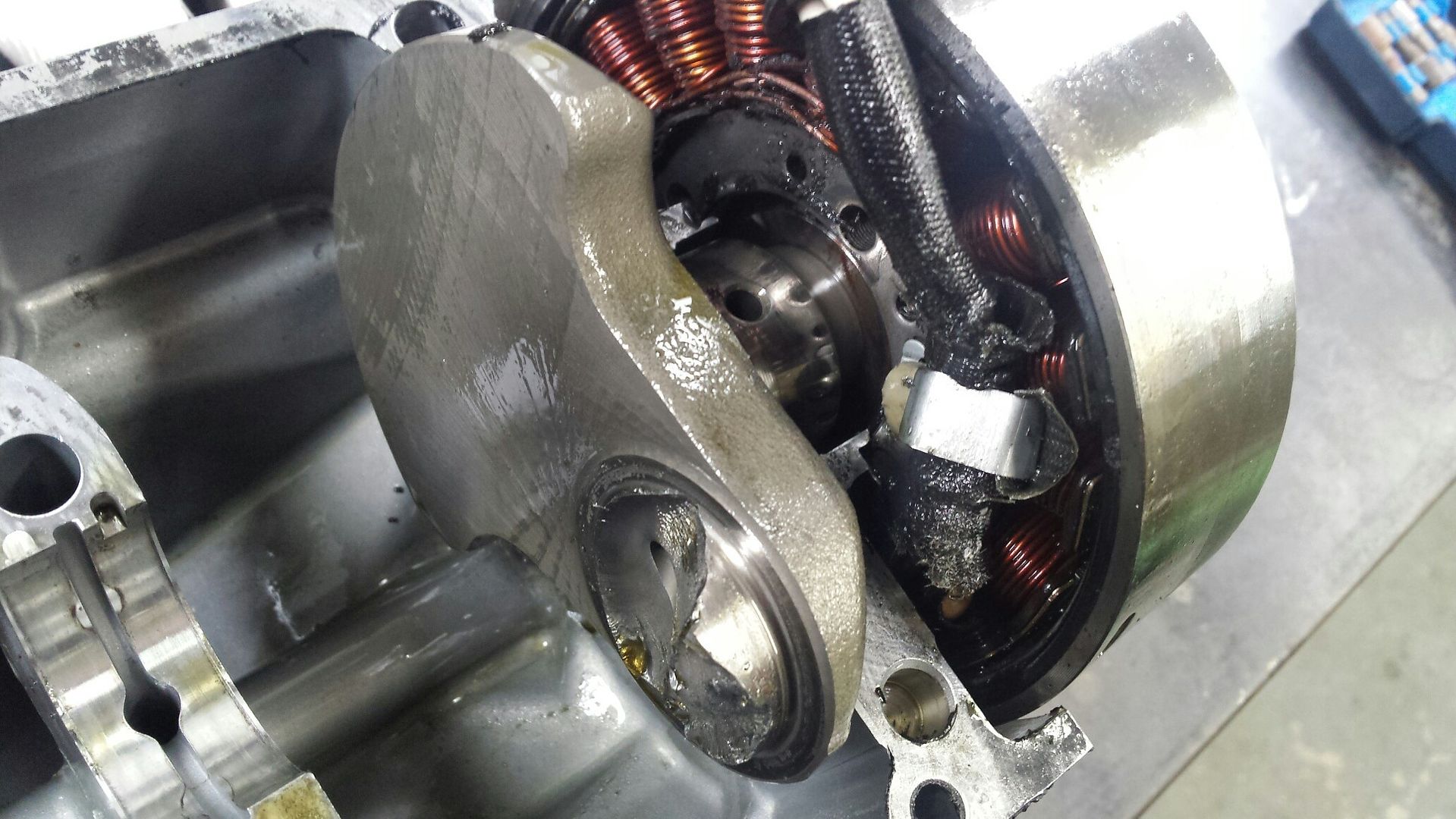

Mostly cleaned up for visual inspection. Confirmation that the vacuum diaphragm is bad, I've never seen one quite that far gone before...

rust/junk that came out of the petcock, the bung is off of the vacuum port connection:

Cleaned out the last of the gas into the drip pan and got this left behind:

Clearly there is going to be a problem downstream, time to look at the carbs. Pulled the drain plug off the #1 carb, same rust/dirt/mung in the recess so no need to go any further, time to pull the airbox and pull the carbs out for a long dip. Old, dry rubber intake boots make for difficult tugging, but at $35 a piece they are going to stay old and dried up for awhile longer. Carbs out and on the bench.

Initial finger check of the diaphragms didn't show any problems, but not sure what the diff drain plug in the carb on the R is all about yet. Pretty dirty overall. Original "chrome" stickers on the sides of the float bowls. Diaphragm covers should polish up nice. Don't think the golf tee in the vacuum line will make it into the final build. That shortly fuel line connector between the center and R carb prob won't make it either.

New 1/4" clear Tygon fuel line on order for use all around, along with new 3/16 clear overflow line

So much easier to work on this than the R1... Into the carbs later today