Page 1 of 1

questions before chroming parts

Posted: Wed Sep 20, 2017 10:30 am

by jabcb

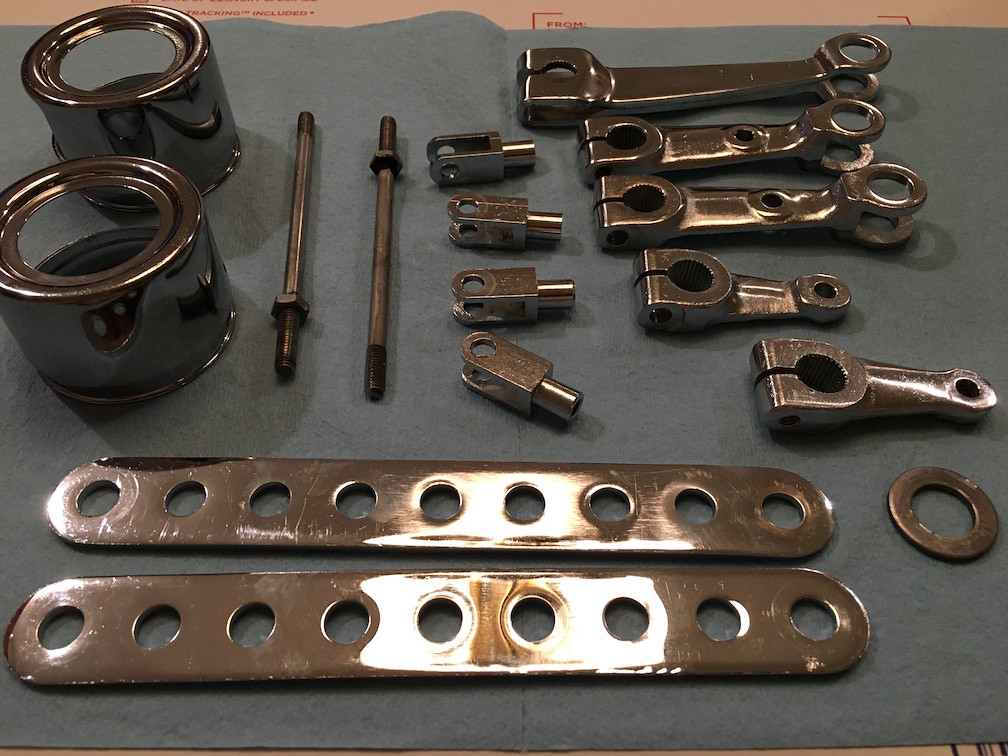

Have not had anything chromed before so I have beginner questions.

Have started getting parts together for the GT550 cafe project.

First grouping of parts is in this pic:

cafe-GT550-0683

cafe-GT550-0683 by

jabcb, on Flickr

How much cleanup/prep work should I do before sending the parts off? (The brake link on the very left is particularly crusty.)

Are there any issues associated with chroming treads?

Anything else?

Will have more parts like the foot-operated levers & kickstart lever.

Haven’t made decision on fenders. Will do fender mods before chroming.

Am going to cut back front fender to be similar to the GT380 project fender, so it won’t have the stays.

Should I separate the front fender into two parts (fender & fork brace) or keep them riveted together?

Re: questions before chroming parts

Posted: Wed Sep 20, 2017 6:07 pm

by joolstacho

The more prep you do, the more it 'should' reduce chroming costs. The least you should do is get rid of the loose rust with a bench wire wheel.

Problem is there will be rust pitting underneath the old chrome, and unless you have the right chemical setup to strip the chrome off you'll have to leave this to the platers. They chemically strip the old chrome off and then use fairly 'quick 'n nasty' methods of polishing the defects out of the steel before chroming, which tends to round off sharp corners etc. Every defect, like pitting in the steel will show after chroming unless the steel is well polished.

Chroming will affect threads, but areas can be masked off. On the other hand, if the thread is not a critical one it should be ok - you may need to run a thread die down the thread if it tightens too much. Certainly do this on any thread that screws into alloy parts because chrome is very hard and can wear a thread in alloy.

I'd certainly detach the mudguard and stays, - the polishing process using BIG mop polishing wheels makes it pretty difficult with stays flopping around.

If you have anything that's bare steel, if you can bear to do the work, you can use files, wet and dry paper, going through the grades to something like 600, then the plater just needs to put it 'on the wheel' briefly to polish before chroming.

Best chroming is 'triple-plate' chroming. After polishing the bare steel, first it's copper plated, then nickel plated, then chrome plated.

Re: questions before chroming parts

Posted: Mon Jan 08, 2018 7:10 am

by jabcb

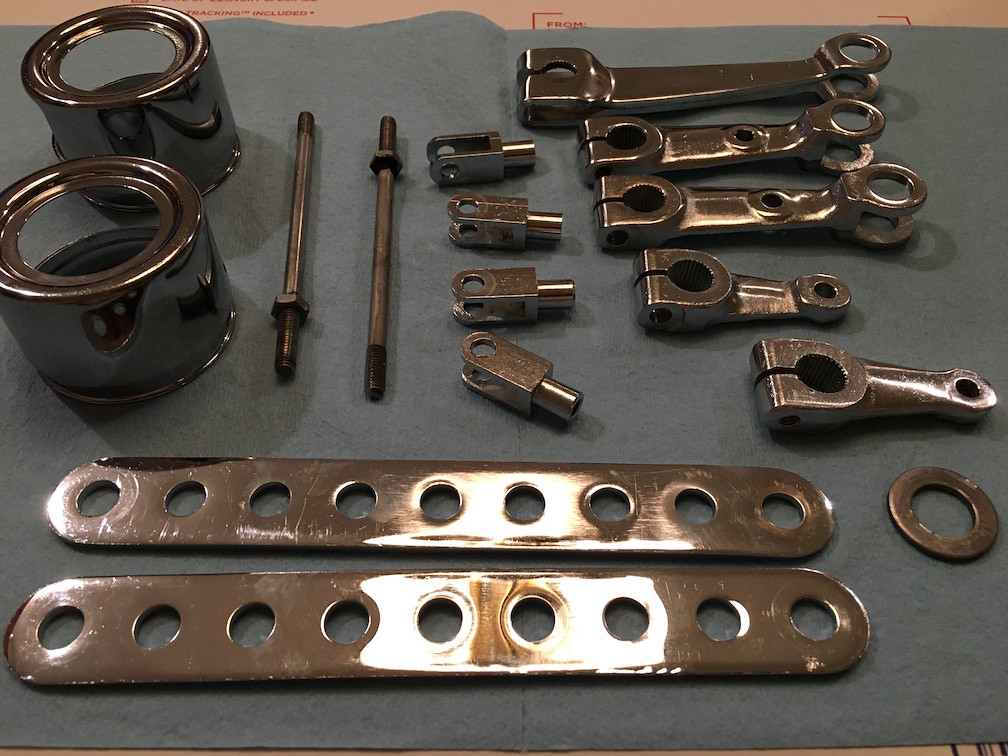

Finally got around to dealing with these parts.

Used a HarborFreight ultrasonic cleaner with 50% SimpleGreen + 50% water. Then Metal Rescue.

The chromed parts look great & I’m going to use them as is.

The two 4LS adjuster rods need some work. No idea why, but the adjust nut turned dark on one side & looks ok on the other.

Included a rusty washer that also didn’t work out well — its still available & I’ll use a new one.

cafe-GT550-0765

cafe-GT550-0765 by

jabcb, on Flickr

Re: questions before chroming parts

Posted: Mon Apr 02, 2018 6:22 pm

by 1T500closertodivorce

I am really impressed about how those parts came out.

Would you recommend the purchase of an ultrasonic cleaner? I am just starting work on a T500J so I have plenty of cleaning to do.

Is a 2.5 liter tank adequate?

Cheers.

Re: questions before chroming parts

Posted: Mon Apr 02, 2018 6:37 pm

by jabcb

I have a super cheap ultrasonic cleaner from Harbor Freight. Haven’t used it for much so far.

Ultrasonic cleaners are popular for cleaning carbs but I’ve never tried doing that.

A parts washer is popular for larger parts. I don’t have one but a mechanic/friend does & has cleaned up some larger parts for me.

There are some topics on ultrasonic cleaners. Search for them & you’ll find a lot better advice than I can give.

Re: questions before chroming parts

Posted: Mon Apr 02, 2018 6:47 pm

by joolstacho

Don't expect 'magic' from an ultrasonic cleaner. Obviously a fair bit depends on the 'pickle' (chemical) used though. We rarely use ours because there are quicker cleaning methods for most parts. Where an Ultrasonic is good is getting at impossible to get to areas such as fine drillings in carbs etc.

There's no substitute for elbow-grease!

cafe-GT550-0683 by jabcb, on Flickr

cafe-GT550-0683 by jabcb, on Flickr cafe-GT550-0683 by jabcb, on Flickr

cafe-GT550-0683 by jabcb, on Flickr