Page 1 of 1

Tearing down - 1968 T20

Posted: Wed Nov 02, 2016 5:27 am

by granitize

Hi All,

New here.

Picked up a 1968 T20 in my cousins barn.

All parts in place, engine not seized.

Clutch, brakes, wires all in good shape COVERED IN OIL, GREASE and GRIME from 25 years.

Tearing it down!

Lots of carbon on the piston heads (do I worry about that?).

I removed both snap-rings, ostensibly holding the elbow pin in place, so I can check out the wear and play on the piston arm.

The pin doesn't seem to want to just slide out.

How do I get these out?

There are a couple of small holes in the tube under the piston head... Are these "auxiliary "retainers" or something?

Re: Tearing down - 1968 T20

Posted: Wed Nov 02, 2016 6:45 am

by akendall1966

Once you have removed the circlip / snap ring the pins can be pushed out. They are generally a snug fit but time will have likely accumulated carbon and other crud making them a little harder to remove.

Heat is your helper warm the piston around the area the pin located to expand the alloy. Get a block of wood to support the piston and press or tap out with a drift and hammer. If you don support the piston you risk putting strain on the conrod and bearing. If they are still not moving soak with a little penetrating oil, leave it a few days, wipe down reheat and try again.

Re: Tearing down - 1968 T20

Posted: Wed Nov 09, 2016 6:50 pm

by granitize

I haven't used heat yet...

Both circ-clips came nicely off of both cyl.

The pins move nice and smoothly for about 1/4 inch in each direction... and then stop... almost like there's another retainer pin or something.

Is this possible?

Do I support the piston with the piece of wood against the block bolts?

Sorry for being thick.

Thanks

And... are rings supposed to fit snugly, or are they fairly loose?

Re: Tearing down - 1968 T20

Posted: Thu Nov 10, 2016 1:41 am

by akendall1966

Yes against the bolts should be enough, but go easy find another way to support if badly stuck so you don't bend them. There won't be a retainer just some carbon build up or other crud on the pin that needs to be forced off.

Re: Tearing down - 1968 T20

Posted: Thu Nov 10, 2016 4:48 am

by rngdng

The scratches that sometime occur from installing the circlips can be enough to cause the sticking. It doesn't take much. Get a long bolt (or allthread) with a head that will cover the hole in the wrist pin, but not extend past the outer edges of the wrist pin, and cut a three inch piece of PVC that is larger that the wrist pin. Put the bolt through, add the PVC, a large washer and nut to the opposite side of the piston. Tighten the nut, and you can gently "jack" the wrist pin out. Works like a charm.

Lane

Re: Tearing down - 1968 T20

Posted: Thu Nov 10, 2016 11:19 am

by granitize

[quote="rngdng"]Put the bolt through, add the PVC, a large washer and nut to the opposite side of the piston. Tighten the nut, and you can gently "jack" the wrist pin out. Works like a charm.

ohhhh... I like that! Good plan.

Re: Tearing down - 1968 T20

Posted: Thu Nov 10, 2016 1:34 pm

by Zunspec4

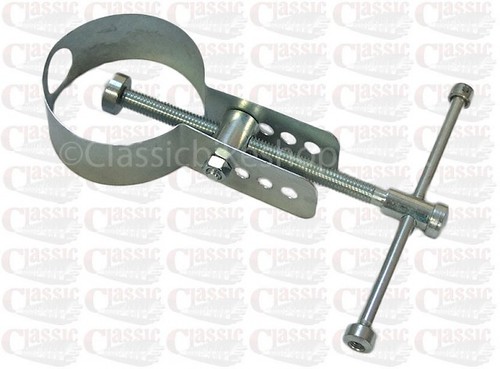

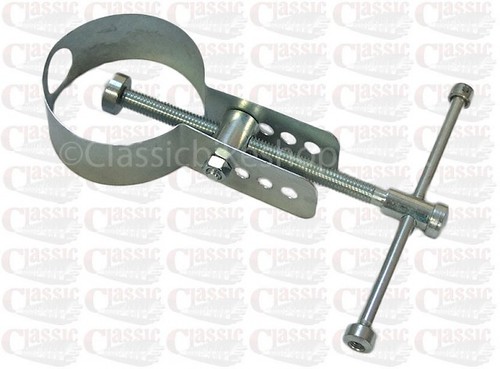

I use one of these, takes the drama out of removing gudgeon pins, using a drift is always a bit stressful.

Cheers Geoff

Re: Tearing down - 1968 T20

Posted: Fri Nov 11, 2016 6:45 pm

by granitize

Found a long nut/bolt/washer, with the right size head, and a piece of copper pipe (padded well of course...).

Worked like a dream.

Thanks for your help.

Now that I have the pistons off I will be taking the side panels off to inspect the ignition and clutch.

Looks pretty clean in there.

I just purchased

https://www.amazon.ca/dp/1588500810/ref ... 7M.MKPW2E4" onclick="window.open(this.href);return false;" onclick="window.open(this.href);return false;" onclick="window.open(this.href);return false;

Cleaning everything up so I can do some measurements, check seals, bearings, gears and wiring.

The exterior of the engine is

covered with 20 year old oil and dirt ... collected in the most bizarre places.

A couple of questions: The manual will help when it arrives.

Any real trouble spots to examine?

1) Are rings fairly tight or do they have some play?

2) How much lateral play on the piston arms should there be?

3) I didn't find a fuse box anywhere... are there fuses?

4) The rubber grommets for the wiring harness and the oil pump lines... do they just pop out with the right pressure?

Don't want to break them but would like to remove before I snap them.

Attached a pic for your perusal... from before I washed it and started the teardown.