Page 1 of 1

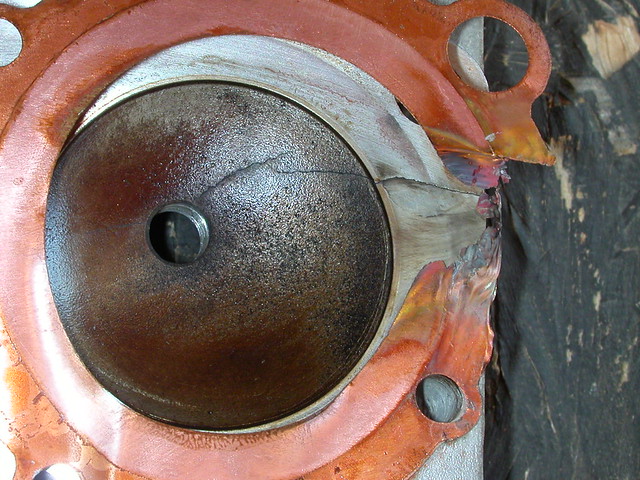

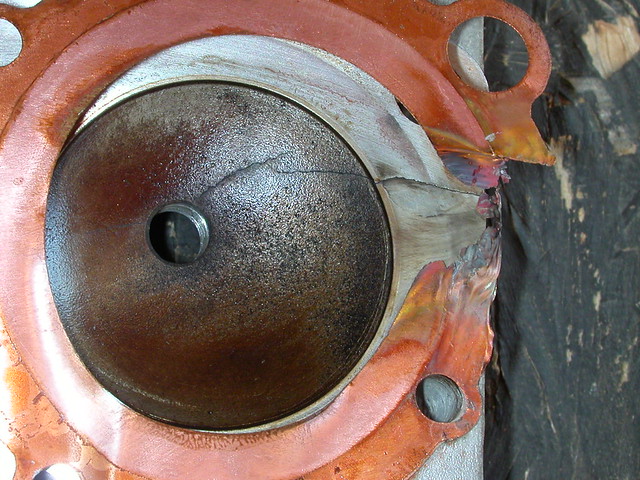

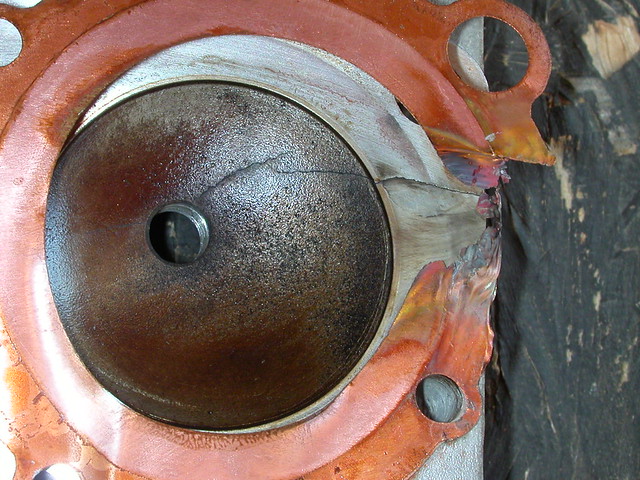

Cracked T500 Head

Posted: Mon Sep 19, 2011 2:32 pm

by Frank

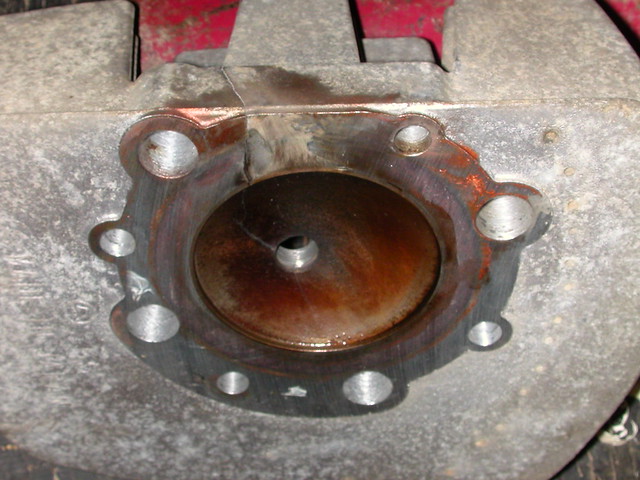

I did this at Loring this past weekend at a land-speed event. It was shaved .040" (1 mm.) Comments, thoughts, etc. appreciated! I've heard that these heads have a propensity for cracking but this took me by surprise. It's not like I was running nitromethane or anything, lol. How can I prevent this from happening in the future?

thanks,

Frank

Re: Cracked T500 Head

Posted: Mon Sep 19, 2011 4:27 pm

by tz375

Frank, That's two different cracks intersecting.

PEDRO or Zookie are the resident 500 guys but I think I'd would be looking at repop air cooled TR heads for that bike.

Re: Cracked T500 Head

Posted: Mon Sep 19, 2011 4:43 pm

by diamondj

Years ago there was a guy on this board that went by the username "Krash". Krash raced T500's and had a continuous issue with cracking the left cylinder head on his race bike. I think he finally figured out that he was milling the heads too much and that there was an inherent weakness in the cylinder head casting as the cracks were always in the same spot and the same head. Don't know if this applies to your situation but I would look into getting a set of TR500 replica heads from Pedro. They will cost you a bit initially but being able to stop worrying about cracking the stock heads should make it worthwhile.

Jim

Re: Cracked T500 Head

Posted: Mon Sep 19, 2011 5:35 pm

by Frank

This was the left head! I didn't know Pedro was making heads, I'll contact him.

Thanks guys. I remember Krash's race stories. I wonder if some of them are still on Eric's site? Have to look...

Re: Cracked T500 Head

Posted: Mon Sep 19, 2011 9:01 pm

by Suzukidave

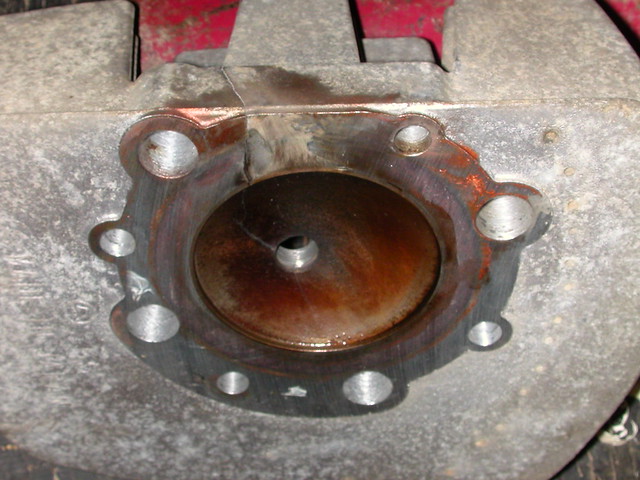

The picture has me puzzled a bit .. the stud hole in the upper right is not where the stud hole in the head is .. how did the hole get so much larger than the rest and not where it should be if the head bolt went thru that hole ?

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 2:12 am

by titan performance

There are 2 different sized studs that retain a 500 head Dave....4 short 8mm bolts, alternated with 4 long crankcase studs. The gasket has been mis-shapen by the cylinder blowing.

I have cracked a few heads in the dim and distant past.........

I'm guessing now, but is the crack between the 2 long studs that are farthest apart? That's where mine always cracked.....and I think it was my reluctance to torque the head down tight enough on the 8mm short bolt between these 2 long studs. As we all know, these short bolts screw into the aluminium of the barrell/jug body, they weaken, wear out, and eventually strip. With a stock motor, I found I could leave out all the 8mm bolts except that corner one where the gap between the long studs is larger, and suffer no problems at all. Ultimately, I inserted a stud into that thread, and secured it with a nut, as I have done in the exhaust ports. I run a slightly ported motor now, with Barton squish heads, and have never suffered any cracks since.

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 5:41 am

by Suzukidave

titan performance wrote:There are 2 different sized studs that retain a 500 head Dave....4 short 8mm bolts, alternated with 4 long crankcase studs.

Ah yes .. i should have looked before i asked

http://www.ozebook.com/compendium/t500_ ... pascal.htm" onclick="window.open(this.href);return false;

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 6:25 am

by Frank

titan performance wrote:I'm guessing now, but is the crack between the 2 long studs that are farthest apart? .... I run a slightly ported motor now, with Barton squish heads, and have never suffered any cracks since.

I'm not sure what you mean by between the 2 long studs. The crack is perpendicular to a line drawn between those studs but doesn't run stud-to-stud (here's another pic that might show it better.) The crack also extends around the edge of the head.

I'd love to get some squish heads. Eric apparently lost his source. What's the deal with Barton heads? Maybe it's not necessary as I'm running stock pipes in my class. Thanks for any info on this.

Frank

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 7:29 am

by Zook-e

My squish head source was from Crooks and that for their personal reasons dried up. Pedro can probably source some.

As for the milled heads, that has only happened to me once and I have used 40 and 60 thou heads. It is very important to heat cycle, completely cool down and retorque the heads at least three times. Each time I have heat cycled the motor the torque specs have changed and needed retorquing. Make sure the cylinder surface is also surfaced and I have used 600 grit sandpaper on a glass surface with wd-40 to do this. Any imperfections can cause a leak. I also coppercoat my copper gaskets.

Some builders use only the 4 large bolts, but I use all 8. Make sure the small bolt hole threads are chased and clean. Helicoil or threadsert them if they are vague at all. And make sure all threads on bolts and studs are cleaned.

Some heads have imperfections in castings that also may cause cracking.

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 7:50 am

by Frank

Thanks Eric. I retorqued twice (I think) and will pay better attention to that - what thickness head gasket do you recommend? I used a Cometic .010" (might have been .012) with coppercoat. I've been thinking of leaving the next set of heads at stock thickness and maybe decking the cylinders to get a bit more compression.

This engine had 145# cold cranking pressure. Does this seen "in the ballpark" to you?

Frank

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 8:31 am

by jabcb

This might help. A NOS T500 left cylinder head is on eBay for $75.

http://cgi.ebay.com/ebaymotors/ws/eBayI ... AUS%3A1123

Re: Cracked T500 Head

Posted: Tue Sep 20, 2011 9:33 am

by ja-moo

On the Kawi H2 heads, under very hard racing use, the outer heads will crack. The solution was to add couple of weld beads along the bottom of the fin, on the side. I also always chamfer all the edges and holes to stop any stressers.

Re: Cracked T500 Head

Posted: Sat Aug 02, 2014 10:39 am

by srech77

Can anyone out there let me know how to go about doing copper head gaskets?? I'm having Eric port the cylinders on my 75 Titan, and he suggested using a copper head gasket to raise the compression slightly.

Doe this mean just using the liquid copper make-a-gasket stuff ... or is there actually a stiff metal copper gasket you can buy somewhere?

Any help appreciated - thanks in advance.

Sterling

Re: Cracked T500 Head

Posted: Sat Aug 02, 2014 1:35 pm

by Frank

Cometic sells 'em but this is what I used when my head cracked. I've run several land-speed events since I replaced with stock aluminum w/o any problems.

Re: Cracked T500 Head

Posted: Sat Aug 02, 2014 7:24 pm

by srech77

Frank wrote:Cometic sells 'em but this is what I used when my head cracked. I've run several land-speed events since I replaced with stock aluminum w/o any problems.

Ah, I see. Well of course, I already have a new set of oem head gaskets and base gaskets ready to go. But once Eric mentioned doing the thinner copper gasket, I was on a mission. Obviously, it would be much easier to use the gaskets I have, rather than sourcing some copper ones.

Also, this is only going to be a street bike, I'm not racing it or anything. I just wondered if having ported heads, chambers, and rejetting required the use of a thinner head gasket, or if I can just use the regular ones ...

I feel so lost sometimes, lol.

thanks -