Absolutely right Kevin and shape of the port is also important. The wider it gets the more gentle the top and bottom curves have to be.

55mm was on an Ocelot 850 motor and non of us knows the provenance of that motor prior to it being measured by john McCann. We don't even know if it worked well or failed spectacularly.

A.G. Bell has a good section in his book on piston rings and port shapes which I keep close by when I'm playing with ports.

Another key figure is blowdown and different motors respond to different amounts at different revs. So for a GT at high revs you might want more blowdown that say a hot rod street motor.

Miscellaneous 750 port tracings

Moderators: oldjapanesebikes, H2RICK, diamondj, Suzsmokeyallan

- Suzukidave

- Moto GP

- Posts: 3980

- Joined: Fri Oct 24, 2008 5:55 pm

- Country: US

- Suzuki 2-Strokes: GT750 x2 97 -1200 Bandit 86 GSXR1100

- Location: Lancaster Pa.

- water cooled

- Yeah Man, the Interstate

- Posts: 704

- Joined: Thu Oct 23, 2008 3:23 pm

- Country: USA

- Suzuki 2-Strokes: 1974 Suzuki GT750

- Location: Medina OH

Well, that certainly addresses my question about intake roofs....ummmm I think. Now I need to find some 75 mm piston.

Actually, a 4mm plate would put my exhaust, transfer and intake roofs, all in the right place based upon that port diagram. All the floors would need to be lowered accordingly...very interesting that the two transfers have different floor dimensions.

Of course this plot is for the 850cc motor and not 748cc so there will be some consideration there...main problem for me is deciding how to deal with the lower piston ring. I dont know that I can raise the block 4mm and keep the lower ring on the tear drop that I left on the roof of the intake port. I'll need a measurement. Right now, the block is up .8mm and the ring is right at the top edge of the intake port at BDC. I might be limited by the dear-drop dimension or have to decide to remove the lower ring.

Actually, a 4mm plate would put my exhaust, transfer and intake roofs, all in the right place based upon that port diagram. All the floors would need to be lowered accordingly...very interesting that the two transfers have different floor dimensions.

Of course this plot is for the 850cc motor and not 748cc so there will be some consideration there...main problem for me is deciding how to deal with the lower piston ring. I dont know that I can raise the block 4mm and keep the lower ring on the tear drop that I left on the roof of the intake port. I'll need a measurement. Right now, the block is up .8mm and the ring is right at the top edge of the intake port at BDC. I might be limited by the dear-drop dimension or have to decide to remove the lower ring.

-

ja-moo

- Yeah Man, the Interstate

- Posts: 554

- Joined: Wed Apr 01, 2009 11:47 pm

- Location: NM USA

- Contact:

You can always re-pin the lower ring to move the gap......water cooled wrote: I dont know that I can raise the block 4mm and keep the lower ring on the tear drop that I left on the roof of the intake port. I'll need a measurement. Right now, the block is up .8mm and the ring is right at the top edge of the intake port at BDC. I might be limited by the dear-drop dimension or have to decide to remove the lower ring.

Visiting from the "K" camp...........

- water cooled

- Yeah Man, the Interstate

- Posts: 704

- Joined: Thu Oct 23, 2008 3:23 pm

- Country: USA

- Suzuki 2-Strokes: 1974 Suzuki GT750

- Location: Medina OH

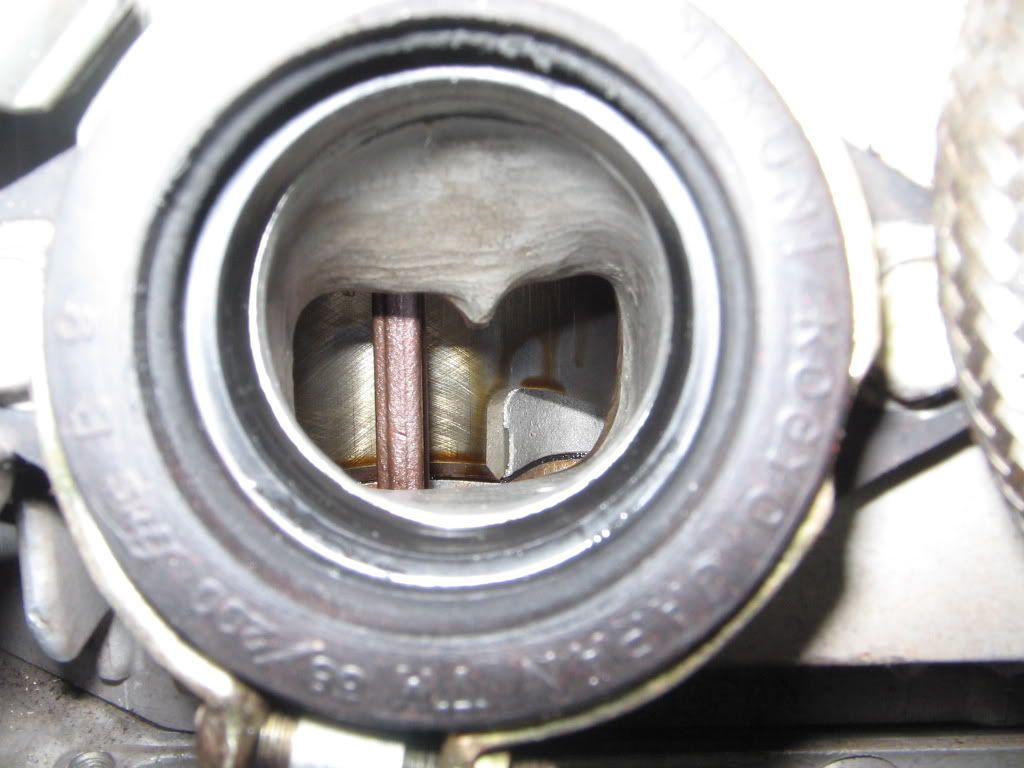

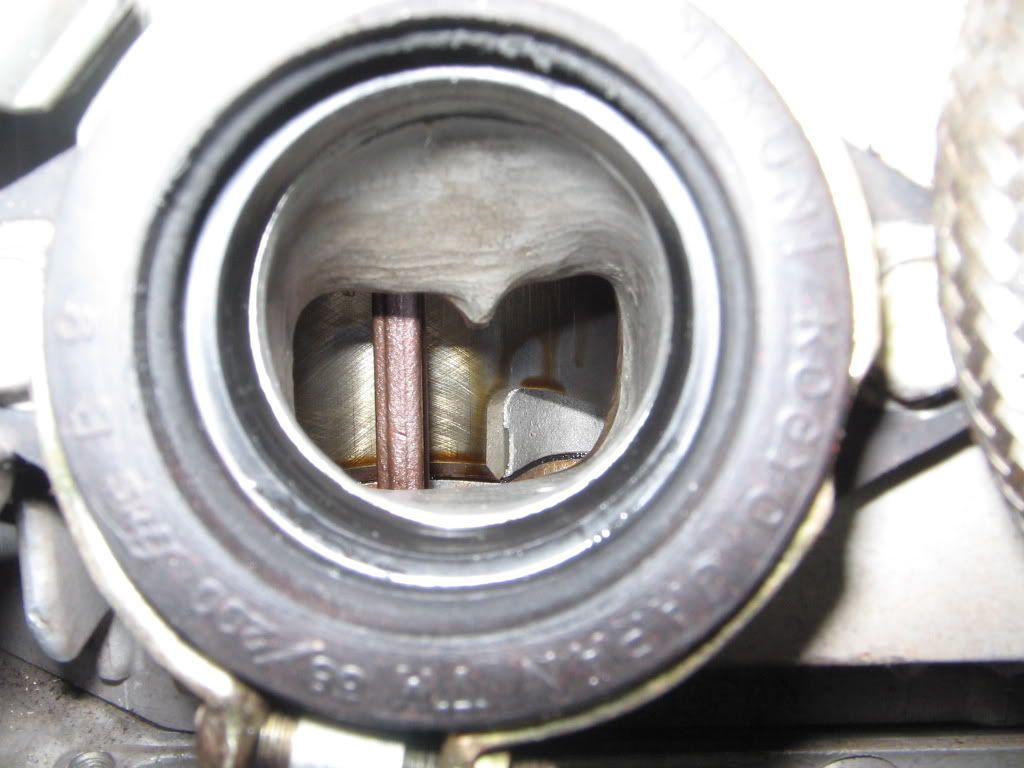

This image might help...not sure if its as much of a pin issue as it is stroke. At BDC, the ring might drop below my intake "tear-drop"

but if I read your comment, the pin and ring gap might also be an issue? I have not considered that one yet but I understand what you are saying. I'll take a close look at that too.

[/url]

[/url]

but if I read your comment, the pin and ring gap might also be an issue? I have not considered that one yet but I understand what you are saying. I'll take a close look at that too.

[/url]

[/url]- tz375

- Moto GP

- Posts: 6204

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

What JA is saying is that if the ring gap and peg are in the wrong place, move them somewhere safe.

The end gap is usually in the wall between ports to prevent the ends from splaying into the port and getting caught.

On a GT, the pins are at the rear and slightly to one side and are in the intake port.

It's actually OK to have the pin in the center of a very narrow port (but not ideal) but it's not OK to have the pin in the center of a wide port and the worst case scenario is having the pin almost at one side of a wide port.

On your race motor it will be necessary to remove the bottom pin and move it to a safe place - like between the exhaust and transfer ports on the left side where there is plenty of meat.

I'd use spring steel and put the new pin in from the top and peen it over, but JA may have other/better ideas.

On your intake port, the roof doesn’t flow much but it does help to stuff the ring back in its groove, so the curve matters.

The end gap is usually in the wall between ports to prevent the ends from splaying into the port and getting caught.

On a GT, the pins are at the rear and slightly to one side and are in the intake port.

It's actually OK to have the pin in the center of a very narrow port (but not ideal) but it's not OK to have the pin in the center of a wide port and the worst case scenario is having the pin almost at one side of a wide port.

On your race motor it will be necessary to remove the bottom pin and move it to a safe place - like between the exhaust and transfer ports on the left side where there is plenty of meat.

I'd use spring steel and put the new pin in from the top and peen it over, but JA may have other/better ideas.

On your intake port, the roof doesn’t flow much but it does help to stuff the ring back in its groove, so the curve matters.