3 into 1 pipe

Moderators: oldjapanesebikes, H2RICK, diamondj, Suzsmokeyallan

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

Bottom line is that if you want a pipe to do exactly what it was designed to do, it's better to go with multiple cones. For cost of production, stamp them out. repeatability is great and unit (variable) costs are low.

I didn't follow the comparison between wave patterns in a chamber versus gas flow in a 4 stroke head, but that's OK. It is indeed possible that a smooth formed chamber may have a softer power curve due to the less precise configuration, but that really comes from the relative shapes of cones.

I didn't follow the comparison between wave patterns in a chamber versus gas flow in a 4 stroke head, but that's OK. It is indeed possible that a smooth formed chamber may have a softer power curve due to the less precise configuration, but that really comes from the relative shapes of cones.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

Sorry for the confusion. I used two different paragraphs, one comparing gas flow and the other wave action. One thing I've noticed about most modern stamped chambers is that there are no defined changes in angles except where the leading edge of the convergent cone meets the neutral mid section, there's a crease forming a sudden change in area. It makes sense because that returning wave is timed for maximum engine speed and any convergence ahead of that point would be timed too soon or for over revving.tz375 wrote:I didn't follow the comparison between wave patterns in a chamber versus gas flow in a 4 stroke head, but that's OK.

I was refering to the transition going into the powerband which should help for street riding or bikes with wide gearing. There are too many variables to say what's going to work best overall but the smoother angle transition allows for a powerband that can start earlier but softer and exponentially increase in power as engine speeds peak. On paper, it works but in the real world, ...?tz375 wrote:It is indeed possible that a smooth formed chamber may have a softer power curve due to the less precise configuration, but that really comes from the relative shapes of cones.

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

yes and no

To smooth the power curve and transition, all we do is to use cones with smaller angles for a longer weaker pulse.

For a street pipe, we could also select a tuned length that matches a resonant speed either at lower rpms for a wider overall effect or shift it to higher revs tan the bike could achieve for a long stretched powerband.

It's the old story about skinning cats - there's more than one way to do it. Just don't tell our cat I said that.

To smooth the power curve and transition, all we do is to use cones with smaller angles for a longer weaker pulse.

For a street pipe, we could also select a tuned length that matches a resonant speed either at lower rpms for a wider overall effect or shift it to higher revs tan the bike could achieve for a long stretched powerband.

It's the old story about skinning cats - there's more than one way to do it. Just don't tell our cat I said that.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

I have to agree with you because the smooth transitions on the pipes have such a low angle and duration that they couldn't produce any noticeable power increase at that point. Also, looking at the better known aftermarket brands, I see they're stamped with sharp transitions and only blend angles between inlet and diffuser (as do most). It's an age old design that that still works today.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

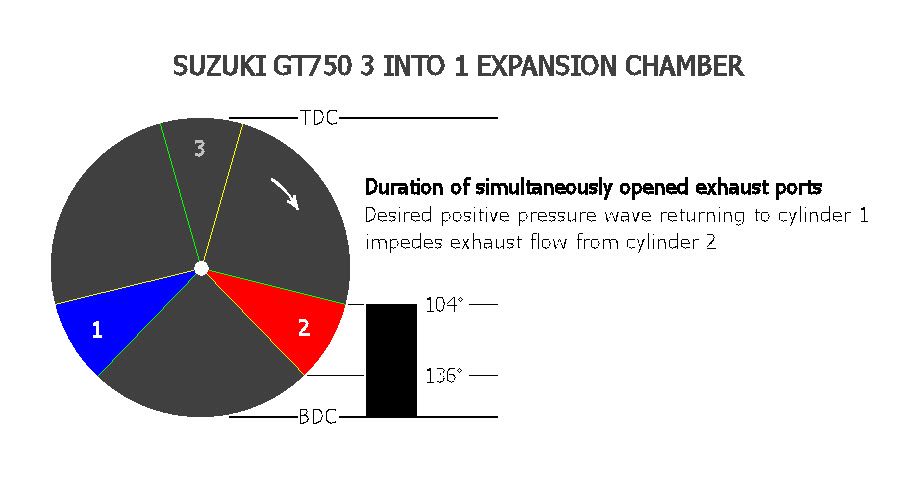

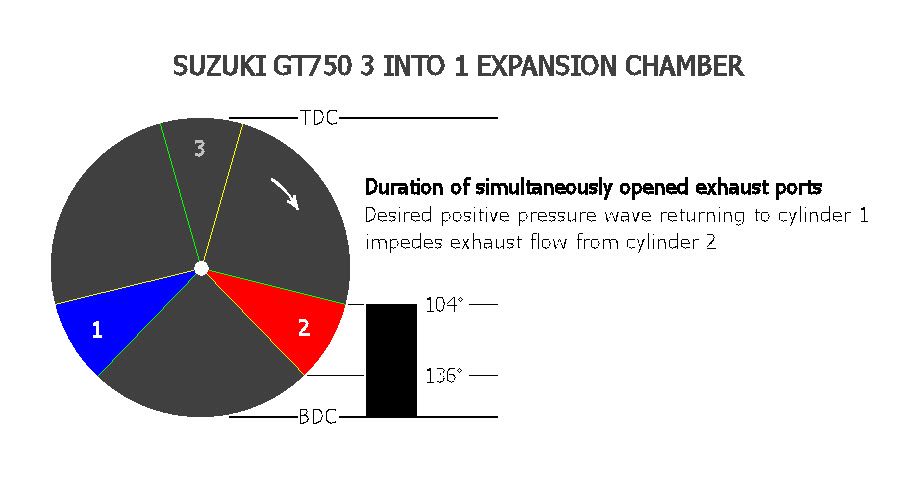

Here's a diagram showing the problem with a 3 into 1 chamber.

What it doesn't show is that even after cylinder 1 port has closed, any remaining reverberation will continue to bombard cylinder 2.

What it doesn't show is that even after cylinder 1 port has closed, any remaining reverberation will continue to bombard cylinder 2.

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

Nice chart. Let's extend the explanation a little. The first thing to consider is engine speed. Waves arrive as the port closes, only at resonant speed. At less than that speed, the wave arrives too late and above that speed it arrives too early.

At lower speeds a three into one acts much like any other single pipe with waves arriving out of synch and not really helping or hurting power. The closer engine speed gets to resonant, the more of an issue interfering waves will become. At peak torque where the pipes should be fully resonant, the waves do start to overlap. Waves can either travel through each other or they can interfere. let's assume a worst case scenario that all waves traveling in opposite directions cancel out.

Let's ignore wave motion for a moment and confine our interest to actual gas pressure in the pipe. As the exhaust port opens, at say 100 degrees ATDC, the pressure in the header is around 2 atmospheres, and it quickly drops to 1.2-1.4 Atm. By BDC, it will be around 0.8atm sucking gas through the transfers and up and out the exhaust. In a well designed system at the right speed, that returning stuffing wave returns to the port just before it closes at say 100 degrees BTDC, and the pressure rises again to 1.5 atm (in a good system).

What does all that mean? Let's consider a well developed pipe at peak torque revs. #2exhaust port opens with 2atm of pressure as port 1 is at 40 degrees ABDC and the pressure should be slightly below atmospheric (but rising) in #1 at that time. So that pressure wave starts to pressurize the #1 header and it inhibits outward flow on #1 slightly. The effect is that #1 doesn't fill as well as it should and power is reduced compared to 3 pipes of the same dimensions. #3 has the same effect on #2 as #2 does on #1 and in addition its ex port opens at 20 BTDC (#1) and closes when #1 is at 140ATDC. It's unlikely that there will be much conflict from that though. So each port opening will potentially impact the pressure in it's neighbor that's closing.

So a 3 into 1 will have some effect to flatten the top of the powerband out compared to single pipes. But if that design is better than stock pipes, the overall effect should be an increase in power at all engine speeds.

Change the exhaust port opening times and all those numbers change. The longer the exhaust event, the more the events overlap. A stock exhaust on a JKL opens at 102 degrees ATDC, close to our example, but let's look at say a ported M/A/B with say exhaust opening at 36mm or 90degrees ATDC.

Ports open and close 10 degrees earlier & later and the overlap between cylinders rises by 20 degrees, so they interfere more with each other. Each case would have to be modeled to estimate the effects on that engine over a whole rev range.

Deduction: - On a stock early motor, a 3 into 1 with mild chamber should be capable of increasing power at all engine speeds.

- On a tuned motor with a more developed pipe, the interference between cylinders will seriously inhibit power at higher engine speeds. Whether that interference makes less power than stock or just less than might be possible with three pipes is less clear.

- A well developed pipe with strong wave action will have more of a loss of potential than a less well developed pipe. In other words, a simple small three into 1 should not suffer as much as a "good" pipe design.

The other issue of course is the collector which seriously disrupts waves.................More on that another day

At lower speeds a three into one acts much like any other single pipe with waves arriving out of synch and not really helping or hurting power. The closer engine speed gets to resonant, the more of an issue interfering waves will become. At peak torque where the pipes should be fully resonant, the waves do start to overlap. Waves can either travel through each other or they can interfere. let's assume a worst case scenario that all waves traveling in opposite directions cancel out.

Let's ignore wave motion for a moment and confine our interest to actual gas pressure in the pipe. As the exhaust port opens, at say 100 degrees ATDC, the pressure in the header is around 2 atmospheres, and it quickly drops to 1.2-1.4 Atm. By BDC, it will be around 0.8atm sucking gas through the transfers and up and out the exhaust. In a well designed system at the right speed, that returning stuffing wave returns to the port just before it closes at say 100 degrees BTDC, and the pressure rises again to 1.5 atm (in a good system).

What does all that mean? Let's consider a well developed pipe at peak torque revs. #2exhaust port opens with 2atm of pressure as port 1 is at 40 degrees ABDC and the pressure should be slightly below atmospheric (but rising) in #1 at that time. So that pressure wave starts to pressurize the #1 header and it inhibits outward flow on #1 slightly. The effect is that #1 doesn't fill as well as it should and power is reduced compared to 3 pipes of the same dimensions. #3 has the same effect on #2 as #2 does on #1 and in addition its ex port opens at 20 BTDC (#1) and closes when #1 is at 140ATDC. It's unlikely that there will be much conflict from that though. So each port opening will potentially impact the pressure in it's neighbor that's closing.

So a 3 into 1 will have some effect to flatten the top of the powerband out compared to single pipes. But if that design is better than stock pipes, the overall effect should be an increase in power at all engine speeds.

Change the exhaust port opening times and all those numbers change. The longer the exhaust event, the more the events overlap. A stock exhaust on a JKL opens at 102 degrees ATDC, close to our example, but let's look at say a ported M/A/B with say exhaust opening at 36mm or 90degrees ATDC.

Ports open and close 10 degrees earlier & later and the overlap between cylinders rises by 20 degrees, so they interfere more with each other. Each case would have to be modeled to estimate the effects on that engine over a whole rev range.

Deduction: - On a stock early motor, a 3 into 1 with mild chamber should be capable of increasing power at all engine speeds.

- On a tuned motor with a more developed pipe, the interference between cylinders will seriously inhibit power at higher engine speeds. Whether that interference makes less power than stock or just less than might be possible with three pipes is less clear.

- A well developed pipe with strong wave action will have more of a loss of potential than a less well developed pipe. In other words, a simple small three into 1 should not suffer as much as a "good" pipe design.

The other issue of course is the collector which seriously disrupts waves.................More on that another day

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

Do you see any reason why a 3 into 1 with a properly sized straight pipe (constant diameter) attached couldn't perform better than the stock system? I haven't looked inside a stock muffler but I doubt there's much if any use of sound waves after the headers to enhance performance.

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

That's basically what Piper and Bromlech did. They basically had a large collector followed by a big tube. The collector is a problem in that the waves see it as just short headers and a long muffler. Stock pipes have a good taper and belly section but instead of a baffle cone, they have a flat plate in a longer belly section. For stock ports, stock pipes work remarkably well.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

The plate would reflect a strong low duration positive wave. Good for the stock low duration port timing.

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

One would expect it to reflect a strong stuffing wave of very short duration. I suspect that because nothing flows in the "corners" and the gas there is stagnant, it's quite possible that it acts lie a short conventional baffle cone - but with "flexible" walls.

Very interesting. A flat plate combine with a stepped baffle tube changes things about a bit. In fact it creates a couple of pressure spikes that don't ravel well as waves and tend to dissipate wave propagation. The result is a flat torque curve from 4500 to 6000 with very different (lowwer) curve that if there was a conventional baffle cone.

BTW, those kart pipes are really tricky little beggars. I finally worked out how to model them and then realized that the chambers are almost the opposite of ours. a Conventional chamber with say two diffuser cones has the first at a shallow angle and the second at a greater angle. The idea is that the first generates a wave action and then the second one adds to that action.

Kart cones start off steepest on the first and then gradually decreasing angles. In cross section it looks almost parabolic. It generates a strong peak which keeps on going like the energizer bunny.Then the clutch for 10k and live from 10-14,000. Insane technology but really interesting.

Very interesting. A flat plate combine with a stepped baffle tube changes things about a bit. In fact it creates a couple of pressure spikes that don't ravel well as waves and tend to dissipate wave propagation. The result is a flat torque curve from 4500 to 6000 with very different (lowwer) curve that if there was a conventional baffle cone.

BTW, those kart pipes are really tricky little beggars. I finally worked out how to model them and then realized that the chambers are almost the opposite of ours. a Conventional chamber with say two diffuser cones has the first at a shallow angle and the second at a greater angle. The idea is that the first generates a wave action and then the second one adds to that action.

Kart cones start off steepest on the first and then gradually decreasing angles. In cross section it looks almost parabolic. It generates a strong peak which keeps on going like the energizer bunny.Then the clutch for 10k and live from 10-14,000. Insane technology but really interesting.

Last edited by tz375 on Thu Mar 22, 2012 5:01 pm, edited 1 time in total.

-

diablo

- On the main road

- Posts: 106

- Joined: Sun Jan 29, 2012 7:53 pm

- Country: canada

- Suzuki 2-Strokes: 1976,1975,1973 gt 750

- Location: eastern canada

Re: 3 into 1 pipe

with a 3 into 1 on the older model engines, could you advance the timeing at all to compensate for the restriction in the pipe? How many degrees and what would the advance look like on the timeing marks if one don't have a dial gauge?

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

Ignition timing determines the starting point for the burn which needs to reach peak cylinder pressure at approx 15 degrees ATDC. If a pipe is more restrictive than stock and that raises pipe temperatures and cylinder temperatures, then timing would need to be retarded to compensate for that.

Advancing ignition makes no difference to pipe flow or wave forms - beyond changing gas temperature and speed of sound in the pipe. You could in theory retard the ignition to deliberately create a situation where more fuel is unburned in the combustion chamber and burns in the pipe. That would raise pipe temps and effectively shorten the pipe and allow the motor to rev slightly higher than stock. That's not a great trade off - less efficient combustion (less power) for higher revs.

3 into 1 is not necessarily restrictive, it's just less efficient at returning pressure waves. Many are less efficient in flow as well, but even a great 3 into 1 will never be as good as 3 well designed pipes.

Advancing ignition makes no difference to pipe flow or wave forms - beyond changing gas temperature and speed of sound in the pipe. You could in theory retard the ignition to deliberately create a situation where more fuel is unburned in the combustion chamber and burns in the pipe. That would raise pipe temps and effectively shorten the pipe and allow the motor to rev slightly higher than stock. That's not a great trade off - less efficient combustion (less power) for higher revs.

3 into 1 is not necessarily restrictive, it's just less efficient at returning pressure waves. Many are less efficient in flow as well, but even a great 3 into 1 will never be as good as 3 well designed pipes.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

If the plate is perpendicular to the walls, the sound is returned more or less as an echo but passing thru the diffuser cone and the curve in the header (coming and going), turns that uniform wave into a short chain of reverberations so by the time the wave gets back to the port, the resultant duration of positive pressure lengthens somewhat. It seems contrary to a chamber designed for a wider powerband but it really doesn't seem to have a coventional powerband associated with a good chamber especially that of a high angled, short inversion cone. The plate also acts as a very effective muffler. Anything sound that hits it gets another dissipating round trip inside the chamber.tz375 wrote:One would expect it to reflect a strong stuffing wave of very short duration. I suspect that because nothing flows in the "corners" and the gas there is stagnant, it's quite possible that it acts lie a short conventional baffle cone - but with "flexible" walls.

Very interesting. A flat plate combine with a stepped baffle tube changes things about a bit. In fact it creates a couple of pressure spikes that don't ravel well as waves and tend to dissipate wave propagation. The result is a flat torque curve from 4500 to 6000 with very different (lowwer) curve that if there was a conventional baffle cone.

As for the gases, I like what you have to say because they can't be easily "mapped" to determine their effect like the predicable sound waves. I've always limited the manipulation of any gas pressures to temperature/sound speed and outlet pipe bleed rate because in "real" expansion chambers the gases aren't stagnant and in the case of the plate with corners, I would have assumed gases are just too elastic to have any control of wave propagation although I believe simulations show otherwise.

- tz375

- Moto GP

- Posts: 6213

- Joined: Mon Nov 03, 2008 10:47 am

- Location: Illinois

Re: 3 into 1 pipe

What I see with MOTA is a steep spike at any sharp change in section that disrupts flow and wave propagation. Sharp changes in section are highly disruptive to the noise aspect as well as to the power enhancing aspects of the design. In theory a sound wave hitting a flat (closed) end plate will return the same wave with the same sign and similar energy less a small amount from the reversion. Such a wave should be a simple reflection and will reflect the wave coming down the pipe. The kicker here is that unlike a straight tube, the first part of the chamber is expanding, so the wave form and energy are extended over a loner time period. That leads to a longer revers pulse than one might first imagine. But it's much smaller (shorter duration) than a convergent nozzle. A conventional convergent (baffle) cone will work over the time it takes for waves to travel its length and those incoming waves were already "stretched" (wrt time) by the diffuser. So a conventional stuffing wave is a very long duration effect compared to a flat plate, but that's not an instantaneous peak either.stcyr wrote: If the plate is perpendicular to the walls, the sound is returned more or less as an echo but passing thru the diffuser cone and the curve in the header (coming and going), turns that uniform wave into a short chain of reverberations so by the time the wave gets back to the port, the resultant duration of positive pressure lengthens somewhat. It seems contrary to a chamber designed for a wider powerband but it really doesn't seem to have a coventional powerband associated with a good chamber especially that of a high angled, short inversion cone. The plate also acts as a very effective muffler. Anything sound that hits it gets another dissipating round trip inside the chamber.

As for the gases, I like what you have to say because they can't be easily "mapped" to determine their effect like the predicable sound waves. I've always limited the manipulation of any gas pressures to temperature/sound speed and outlet pipe bleed rate because in "real" expansion chambers the gases aren't stagnant and in the case of the plate with corners, I would have assumed gases are just too elastic to have any control of wave propagation although I believe simulations show otherwise.

Interestingly enough many Kawasaki triples had what is effectively a convergent nozzle inside the muffler body to make it into a crude basic chamber shape. Of course the baffle tube design rather messes with the waves and make them less effective than one might imagine they would be.

-

stcyr

- On the street

- Posts: 34

- Joined: Tue Feb 14, 2012 9:24 pm

Re: 3 into 1 pipe

Sounds like we're on the same page but describing things in different words.