It's a miserable cold wet day, so good excuse to stay in the warm and post an update:

Engine is back in the frame, and the electronic ignition is fitted and working.

Looking more and more like a motorcycle again...

Needs paint and indicators back from chroming, otherwise I have everything on hand now to finish the job.

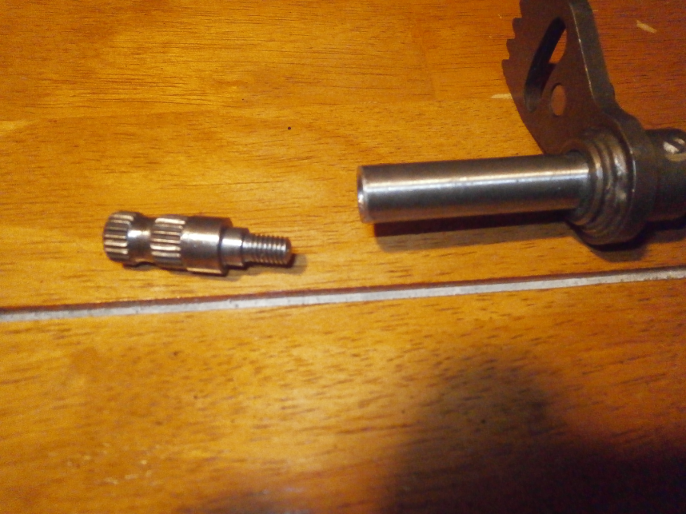

I had 2 good, and 2 leaky check valves, so I though I'd have a go at refurbing before buying replacements. Made a lapping jig to reface the seats.

Still leaked so made some new seats, along with new SS316 balls. Here is my test jig.

I run 2 tests, a vacuum test to measure the cracking point, and then leave them with the feed side connected to a tube of oil at a static head of about 2x the height of the oil tank if full. They all leak some, but by the drop in level in the tube, I am around 0.4cc in 24 hours, but rate seems to slow or stop after this amount is lost. They all hold -120~140 mm/Hg vacuum, about -2.5~2.7 psi. I use a brake bleeder to pull the vacuum and measure.

Been playing around with the idea of making up new replacement oil lines as mine are quite hard and I fear brittle. Here some pics of a rough prototype, tubes are too long at the moment. I am trying 6mm tube between the pump and splitter as I can get banjos that fit 6mm tube so saves making a fitting for the old suzuki pump banjos. Early days but promising so far, going to soak this one in oil to test the bonding out a bit more. Currently if I pull test the bond, the tube yeilds before the joint, so if it holds up after soaking we're good. I'll add the radius to the splitter so they fit the cover in the final version, as I said just rough prototype for now

I have posted elsewhere, but have been converting my headlamp to a more modern buld too.

Hope to be making smoke (good smoke not fires

) before Jan is done.

AK