Page 1 of 1

GT750 taking the motor apart - water pump

Posted: Sat Oct 03, 2009 9:56 pm

by MotoMartin

I'm finally going to tackle the water pump issue. The bike has now been sitting for a while as I tackled some easier projects (fixing up a '78 Honda CB750F2).

Where I left off with the Suzuki was trying to get the water pump out from the bottom. I heated the cases, I smacked away with progressively bigger slide hammers, I cut away the water pump sleeve, I spent countless hours trying to get it out. Now I am resigned to the fact that I will have to disassemble the motor. Are there any tips people have? I have n't yet really looked at the scope of it, do I have to split the cases? Last year I took the cylinder off, and have only done a few miles since, so I am not anticipating any trouble with taking that off.

Cheers,

Martin

Posted: Sat Oct 03, 2009 10:51 pm

by oldjapanesebikes

Indeed - it can be a real pain. take a look at this

thread as it may be an option - otherwise, splitting the cases is generally what you need to do.

Posted: Sun Oct 04, 2009 12:39 am

by MotoMartin

Thanks for the link, it seems like a great idea. What happens to the "swarf" from drilling the hole? I expect some to go inside, oil changes?

Posted: Sun Oct 04, 2009 7:04 am

by oldjapanesebikes

Posted: Sun Oct 04, 2009 7:04 am

by tz375

Martin,

That's a good question. Try greasing the drill bit and tap. The shaft will stop most of the swarf that does fall in and when the pump is pushed out, any swarf will fall straight out of teh water pump cavity.

You will need to use a bottoming tap because the pump shaft is filling the space below the drilling.

Posted: Sun Oct 04, 2009 10:36 am

by Suzsmokeyallan

You can always have someone hold a vacuum near to the hole as you drill, this will definately catch the big pieces which will come upward anyways till it breaks through the casting below.

You could also set a drill at 5mm deep and drill that portion out first, then theres only 1mm of case material to drop onto the shaft itself which could also be vacuumed out as well.

As for tapping the hole it can be done after the cartridge is out so you have plenty to room to allow the tap to go down.

Slipping an eight inch piece of tubing over the casting boss from below would allow the swarf from the tapping of the thread to drop outside the opening where the impeller sits.

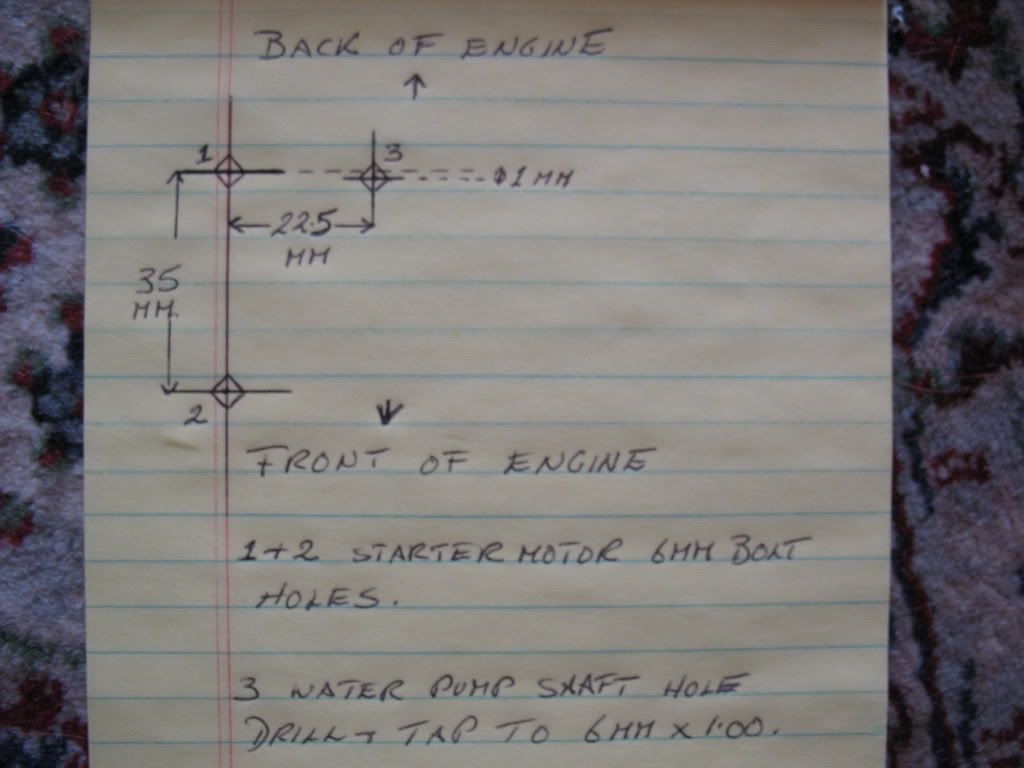

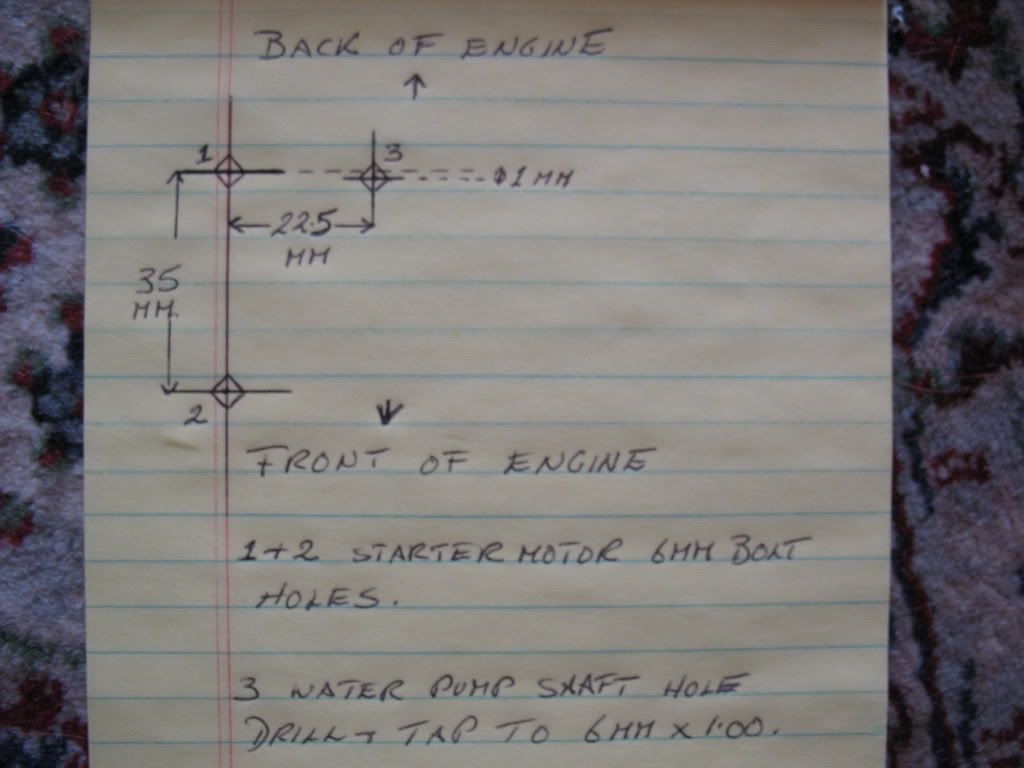

I posted the map drawing over at the original thread but here it is again.

Heres the location of the hole from on top of the case in relation to the two 6mm starter motor bolt holes. I hope this helps anyone whos doing to do this modification.

Posted: Sun Oct 04, 2009 1:52 pm

by MotoMartin

Allan,

Thanks a lot for the template. I will try and attempt this modification this week. I'll post the results.

Posted: Fri Oct 09, 2009 6:57 pm

by MotoMartin

Allan, you have totally saved me from having to dismantle the entire motor. Your template was spot on, and once the hole was drilled, I was able to remove the water pump without much trouble at all. I had spent months trying to remove the pump from below and had shelved the project temporarily because of the overwhelming scope. I can finally give my friend his slide hammer back. Cheers!

Posted: Fri Oct 09, 2009 7:27 pm

by Suzsmokeyallan

Martin thats wonderful news, maybe i need to take out a GT750 case patent now,,,LOLOLOL

Posted: Fri Oct 09, 2009 8:25 pm

by MotoMartin

Allan, what length bolt do you think I need for the new hole?

Posted: Fri Oct 09, 2009 9:43 pm

by Suzsmokeyallan

Since the case is 6mm thick id use a copper washer or fibre washer of approx 1mm thick and a 6mm length bolt. This will mean it will never quite reach the inside of the case but wont be far from it either, allowing max thread contact.

Posted: Fri Oct 09, 2009 11:37 pm

by MotoMartin

Thanks Allan for the bolt size.

I have just ordered the water pump assembly, do you know if the pin for the impellor is included?

Posted: Sat Oct 10, 2009 6:22 am

by Suzsmokeyallan

The pins are available separately but since ive never ordered a pump myself i cant really tell you what it might come with. Sometimes they will supply a small bag with circlips and other times they dont on certain assemblies over the years

The roll pin is stainless steel so make sure you get and use the right thing.

Posted: Sat Oct 10, 2009 11:19 am

by MotoMartin

Thanks Allan. It doesn't show the pin in the photo of the assembly, and it is not clear on the parts fiche if it is included or not.

I have tapped the hole, there are plenty of threads (5-6) to grip the bolt.

The swarf doesn't seam like much of an issue, it just falls out the big water pump opening. In fact making the swarf more sticky may cause it stay inside instead of dropping out the bottom.

Posted: Sat Oct 10, 2009 2:17 pm

by Suzsmokeyallan

The pin part number is 09205-03012, and you must also make sure you have the small o-ring that goes on top of the impeller 09280-10001.