Page 1 of 1

T500 Bleeding the Oil Lines pictures

Posted: Sat Nov 22, 2014 6:00 pm

by LexPaul

I want to make sure that i got all the air out of these 2 stroke oil cylinder lines. What is the best way to bleed these? Should I actually take the lines off the cylinders and let them seep oil out all over the place and make a huge mess of my cases, so that they will never be clean again? Thanks

Re: T500 Bleeding the Oil Lines pictures

Posted: Sat Nov 22, 2014 7:28 pm

by Alan H

No. you take the pump off and use a syringe to pump oil down the lines.

Then when you've put the pump back on, start the bike and pull the pump cable so it delivers maximum oil until any small bubbles in the line have gone. (Fast tickover is all you need.)

THEN take it out for a good 50 mile run so the extra oil will be gone and all will be back to normal.

Make sure that the vent hole in the oil tank cap is clear and plenty of oil in the tank.

If you check level before and after the run, you'll know that oil is being used.

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 5:23 am

by Fritz500

Prior to re-installing the oil lines I fill them with some blue two stroke oil (I use a syringe). Then I fill the oil tank with some red two stroke oil. Start the bike and let it idle. Manually pull the oil pump lever to fully open position and watch the red oil displace the blue. Then go for a ride to clear out any excess oil.

Cheers

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 8:44 am

by pearljam724

I don't know if the T500 has an air bleeding screw like the GT's on it's pump. But, I imagine it does. It helps a great deal to remove the screw until you see oil about to drip from that hole. Tighten the screw. Open and close the throttle rapidly to push the air out. Release the screw again to help air escape. Sometimes it takes a few attempts to get all of the air out from the lines. But, it's very easy to do. It appears in your last picture that pump setting is going to pump a lot more oil than you need. Not, necessarily a good thing. High oil consumption will kill your fuel mileage, etc. When the bike is idling simply pull on that arm with the cable unattached, by hand. Back and forth to push the air out. That should allow you to remove the air without revving the piss out of the bike, instead of using throttle imput. Or annoying your neighbors.

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 3:23 pm

by tricky1962

When I had to do this, I took an M5 nut - need to check the size here, might be M4 - and ground it to half thickness on a stone.

I put the banjo bolt plus washers onto one of the lines, nipped everything up with the thin nut. This left a few mm of thread exposed at the bottom of the bolt. Over the exposed threads I forced a bit of PVC tubing which fitted a syringe and filled each line that way.

Once everything was refitted, I had small bubbles visible in the lines, so rather than mess with different coloured oils, I watched the bubbles move.

If you are really nervous, put some 2 stroke oil into the tank along with the fuel - go 40:1 for example.

I started the bike, and with revs at about 2000 rpm, moved the oil pump lever all the way forwards. Within a few seconds the bubbles advanced down the oil line and disappeared.

Should have taken a bottle of wine round to the neighbours to apologise for the smoke screen I created, but drunk it in celebration instead.

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 4:45 pm

by Vintageman

LexPaul

Some more info.

I assume those pics are current. Did you just rebuild this bike, not run yet?

Does the lines have oil in them now?

Did you take air out of pump?

So you really don't want to get a speck of oil on your cases: Then

Take plugs out of cylinder. put a little oil in cycls. Hold oil pump cam full on your choice how to do that and, push the bike around in gear. Get someone to help if you have a week heart.

It won't take long and lines will fill particularly if you took air out of pump first. Even then still won't take too long

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 6:03 pm

by LexPaul

Here's a little more information.

I do not have a vent in my oil tank cap, and this did not seem to cause any issues.

I just had the motor rebuild, Paul Miller, in CT, did the motor work, including the crankshaft and the motor is smoother than it's ever been, and quiet to boot.

I haven't found a mechanic yet who takes real pride in what they do and so I continually find myself having to fine tune the sloppy work that they dodo. Basically I am over it. I am going to do my own tuning and quit paying these people to do a half ass job. I do most of the basic stuff anyway, but I guess I am going to have to bring it up a notch to keep my sanity. The guy in TN, that put it all together, seems like he just slapped it together.

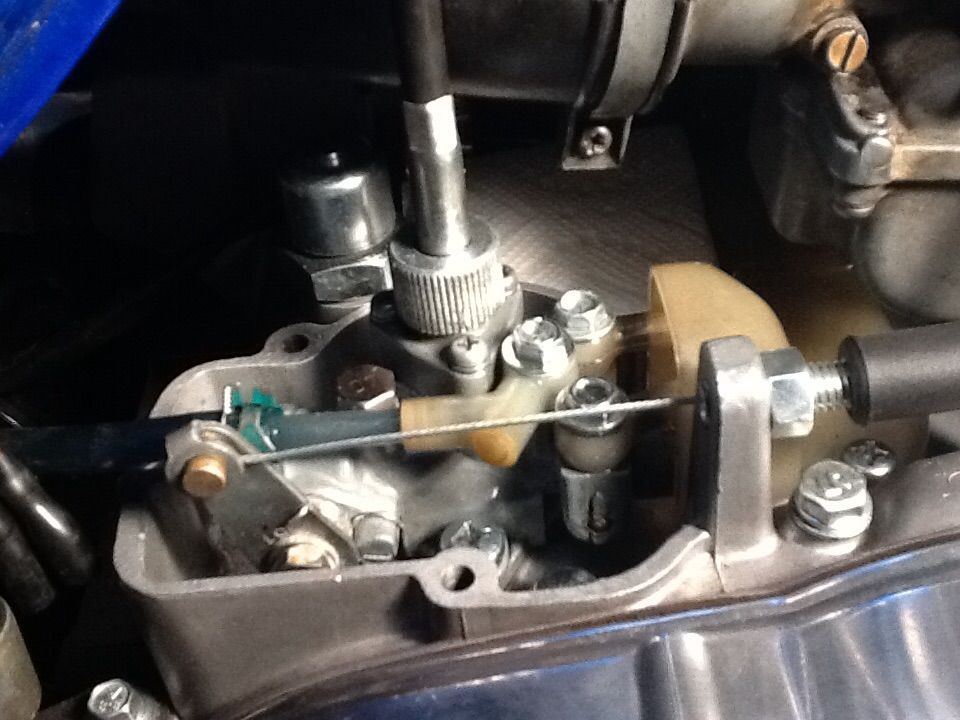

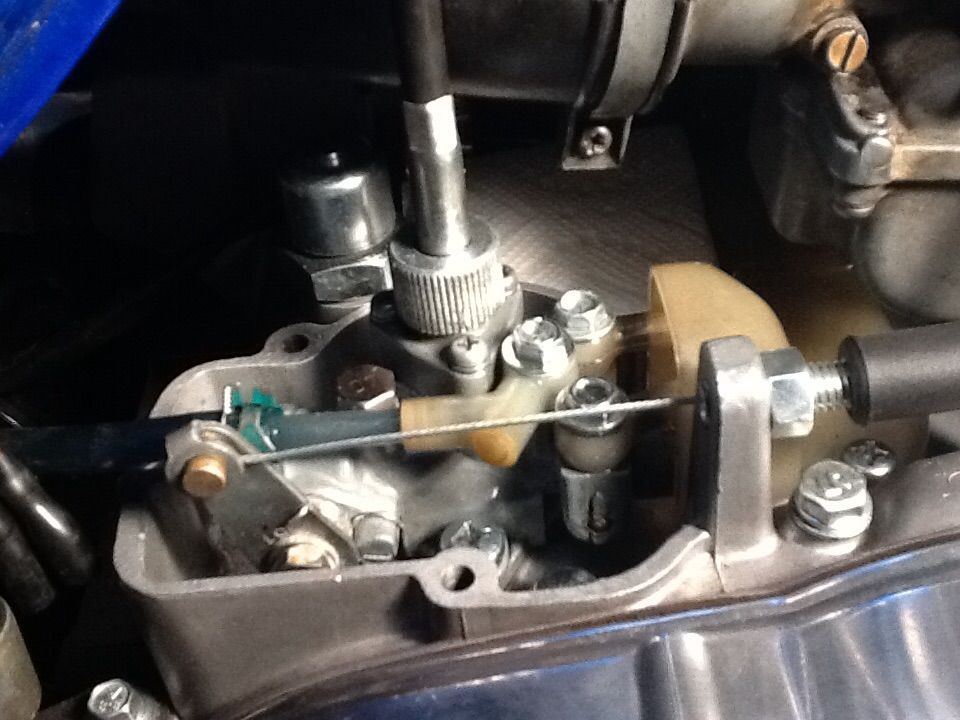

According to the service book, the first picture below shows the cable setting is still on over consumption of oil. I adjusted the screw out as far as I could and the setting is still too rich.

The second picture shows where the arm should sit if the two adjustment lines are correctly aligned, if you look closely, you can see the two notches in the steel.

So, before I take the gas tank off, is there another adjustment place on this cable, at the other end? I could cut the cable at the oil pump end and squeeze on a new cable end nipple there, but not sure if that is ill advised?

Makes me wonder if that cable was not correct for the bike or something. Let me know your thoughts.

Thanks again,,

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 7:22 pm

by pearljam724

You have the correct attitude on working on the bike yourself. The cap must vent, that will allow proper oil flow from the tank to the pump. If your cap does not have a hole in it. Simply, drill a pin hole in the center. Just large enough for air to escape. I don't know exactly how that cable is set up on the T500. But, all injected 2 strokes basically have the same set ups. There should be a way to adjust the other end of the cable. Assuming it's attached to your throttle, etc. It will help to screw out that threaded rod with the nut to take out the slack. But, it appears to me. That you have a large amount of slack. Meaning it will also need adjusted at the other end to take up that large amount of slack. But, start with that piece at the pump. There may be enough adjustment there to do the job. If not, you'll have to adjust the other end also. The cable is more than likely, the correct length. You just need to adjust it. Sometimes, they are routed incorrectly. Making the adjustment not possible. Work with both ends as is first. If that doesn't work. Investigate, the cable being routed correctly. Being your motor was just rebuilt. The builder likely had the pump adjusted higher than normal. Which is the correct thing to do. But, after it's break in period. You don't want high oil consumption for a lot of reasons.

Re: T500 Bleeding the Oil Lines pictures

Posted: Sun Nov 23, 2014 9:37 pm

by Bloop2

LexPaul wrote:I do not have a vent in my oil tank cap, and this did not seem to cause any issues.

No need to drill a hole in the oil tank cap, the T500 oil tank has a vent tube on the backside of the oil tank near the top.

Re: T500 Bleeding the Oil Lines pictures

Posted: Mon Nov 24, 2014 11:58 am

by Vintageman

Isn't the screw out making setting put more oil, not less?

Lever tilted toward back of engine is off direction

You also have a little adjustment right at the twist throttle where the cable exists. There is an adjustable coupling -cable end should move in-out coupling end 1/8 inch or so or too tight. Also make sure the cable harness is not pinched under tank area.

I don't care who you choose to do work. No one cares more than you unfortunately. That's why I could never make a living do vintage restoration (nor I am skilled enough)

Re: T500 Bleeding the Oil Lines pictures

Posted: Mon Nov 24, 2014 3:45 pm

by ConnerVT

Changing the length of the cable to the oil pump won't gain you anything.

The cable will travel the same amount (closed to open throttle) regardless of its length. That travel distance is whatever the throw of the slides in the carb are - from idle position to full open.

Set the oil pump arm to align the marks when at full throttle. If the cable is lightly slack when at idle, that's fine. Pump still moving oil.

But be careful - don't ride with the pump cover off, as the slack cable will allow the brass cable end to disappear while you ride. I've lost two of the little bastards already!